RICKENBACKER AND MADELEINE STRINGS ACOUSTIC GUITARS

THE BUILD PROCESS

TOP BRACING

This slide show follows roughly a step-by-step progression.

Slides advance every 10 seconds, but you can also go forward or backward using the arrows on each slide.

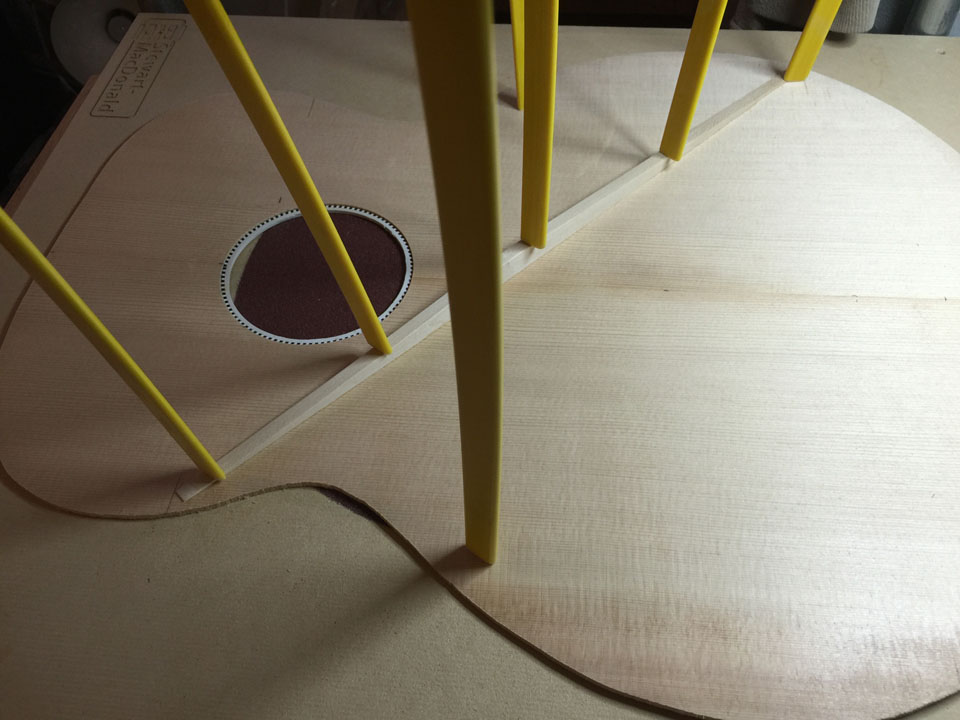

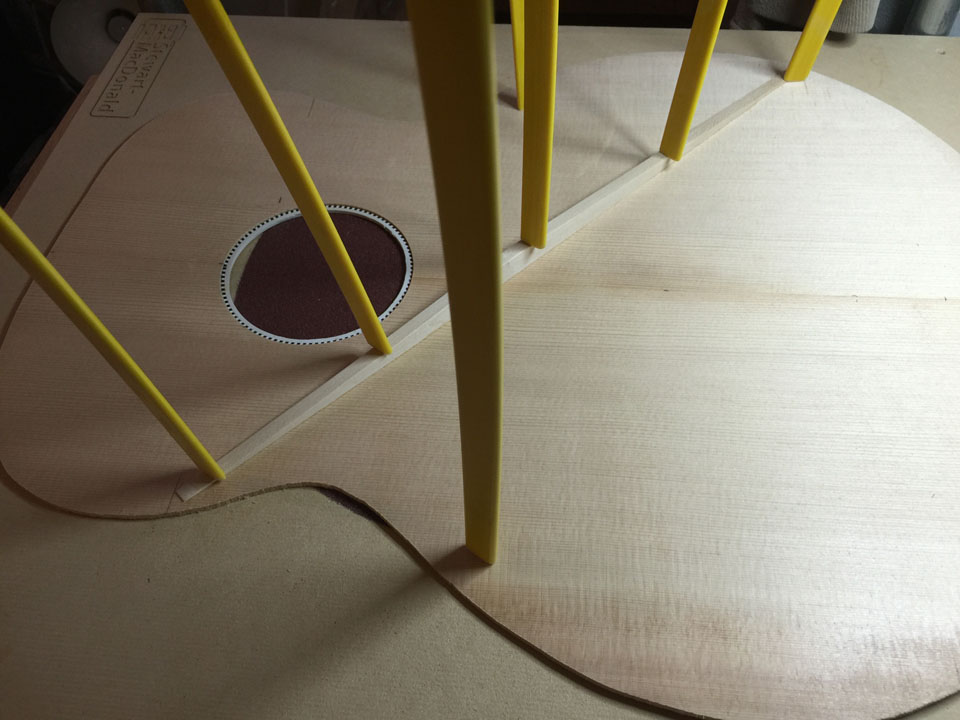

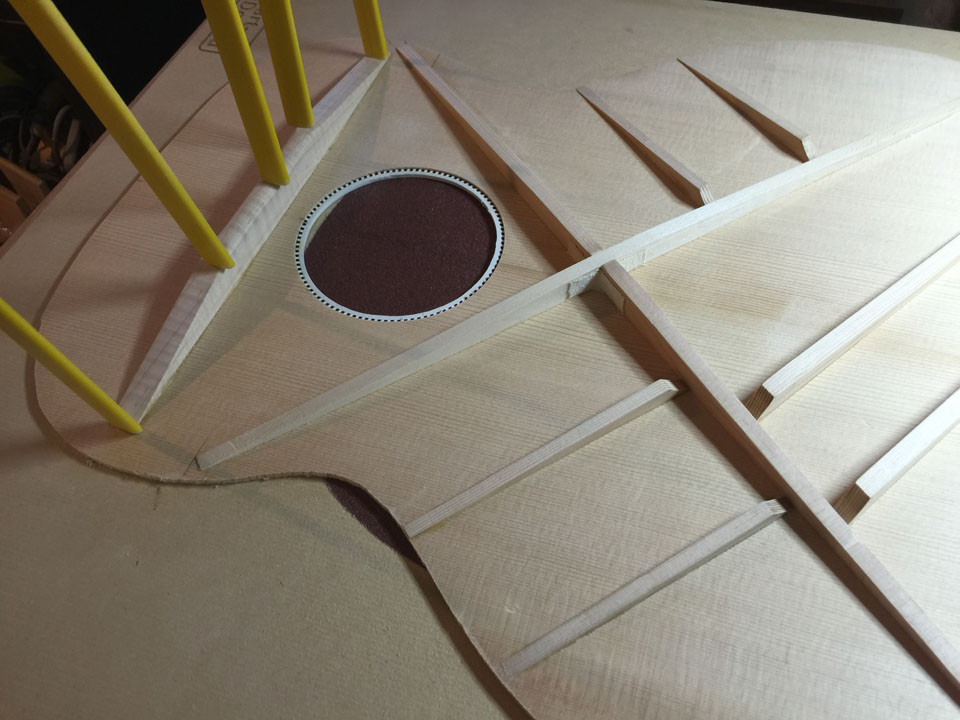

A 700C JUMBO TOP RECEIVES ITS FIRST BRACE. BRACING PATTERN IS MORE COMPLEX THAN BACK BRACING, BEGINS WITH AN "X" BRACE.

ANOTHER VIEW OF THE FIRST LEG OF THE "X" BRACE. AS WITH THE BACK, BRACES ARE HAND-SHAPED AND TAPERED.

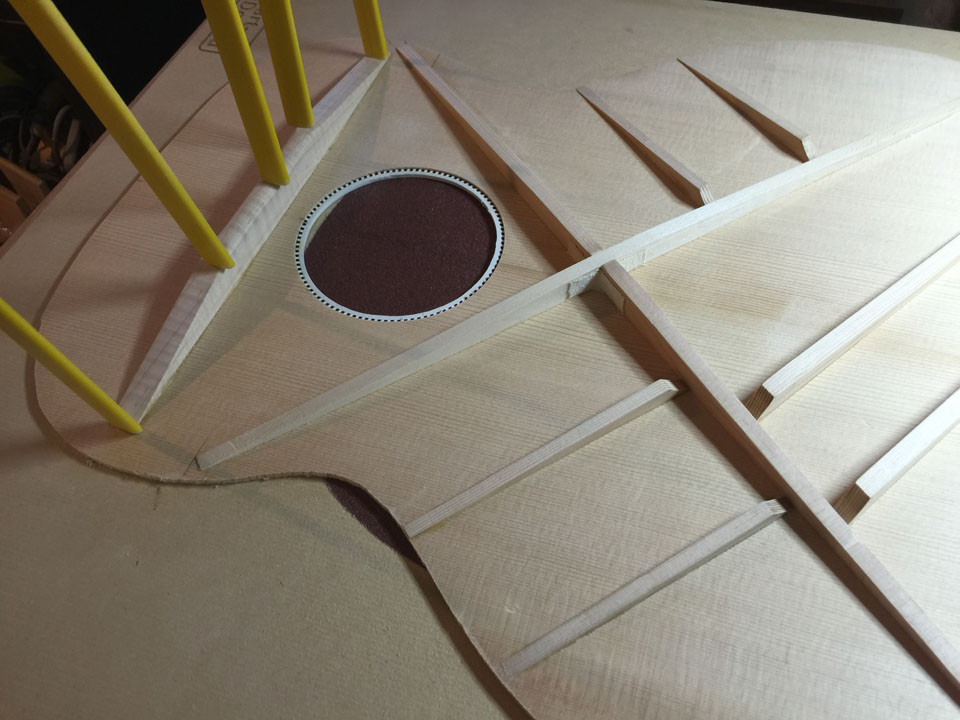

THE SECOND LEG OF THE MAIN "X" BRACE IS GLUED INTO PLACE. THE TWO LEGS MEET BELOW THE SOUND HOLE. THE POINT OF THEIR INTERSECTION DETERMINES THE SOUND BALANCE OF THE GUITAR.

ASSYMETRIC LOWER BOUT BRACES ARE INDIVIDUALLY CUT TO LENGTH, HAND-SHAPED, AND GLUED INTO PLACE. NOTE LINEN REINFORCEMENT STRIPS AT THE JUNCTION OF THE "X" BRACE.

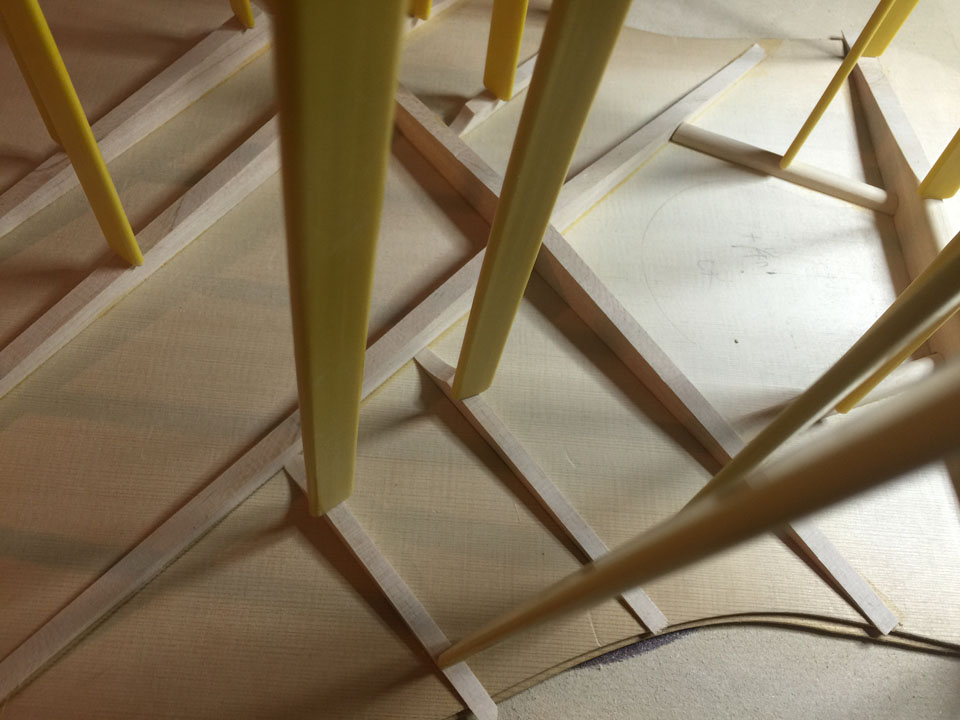

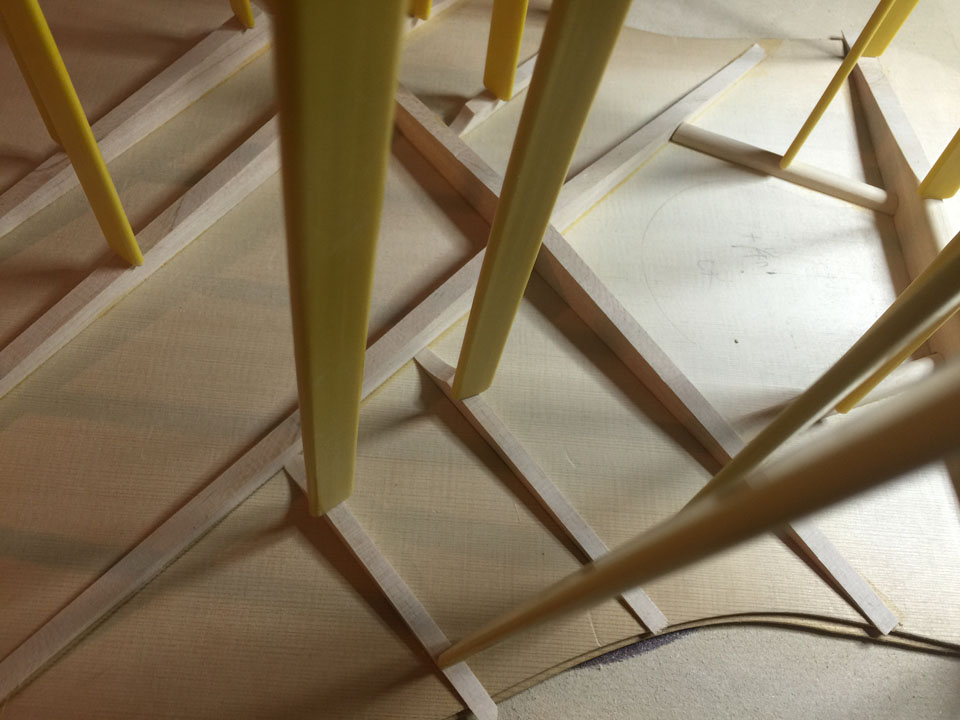

MORE AUXILIARY BRACES ARE ADDED. PURPOSE OF THESE BRACES IS TO ALLOW TOP TO VIBRATE IN A SPECIFIC WAY, YET STILL RESIST STRING TENSION. STRONG AND LIGHT ARE THE BYWORDS OF THE PROCESS.

NEARLY-COMPLETED TOP RECEIVES ITS TRANSVERSE NECK BRACE. THE "L"-SHAPED NECK HEEL BRACE GLUES TO BOTH TOP AND THIS TRANSVERSE BRACE.

THE TRANSVERSE NECK BRACE IS MADE FROM HARD MAPLE FOR STRENGTH AND STABILITY.

FINAL AUXILIARY LOWER-BOUT BRACES AND SOUNDHOLE BRACES ARE CUT, SHAPED, AND GLUED.