RICKENBACKER AND MADELEINE STRINGS ACOUSTIC GUITARS

THE BUILD PROCESS

FINISHING AND PAINTING

This slide show follows roughly a step-by-step progression.

Slides advance every 10 seconds, but you can also go forward or backward using the arrows on each slide.

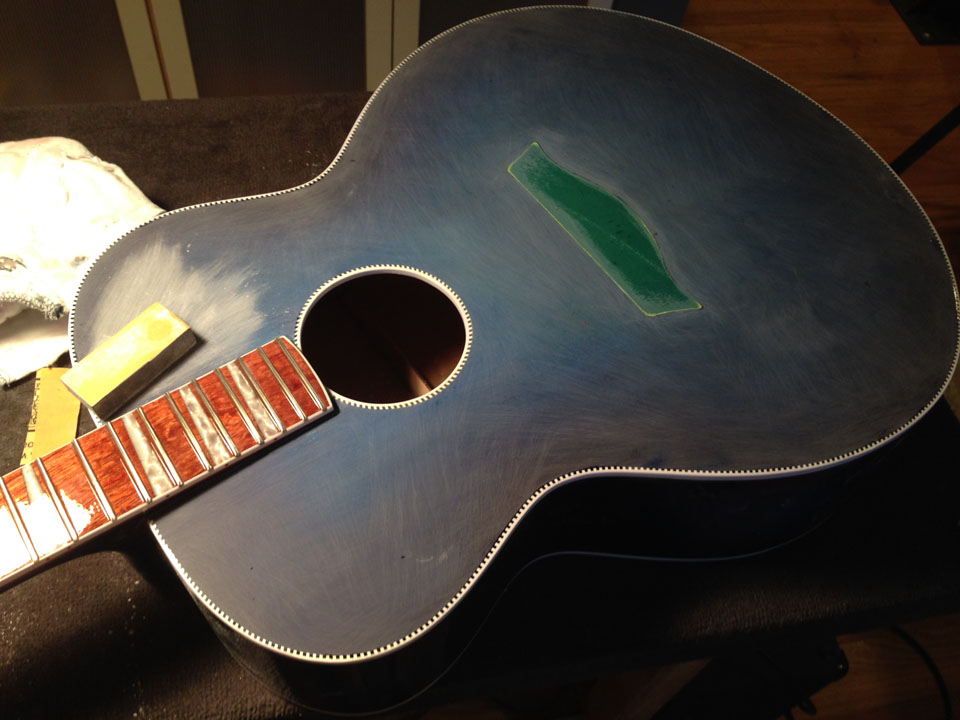

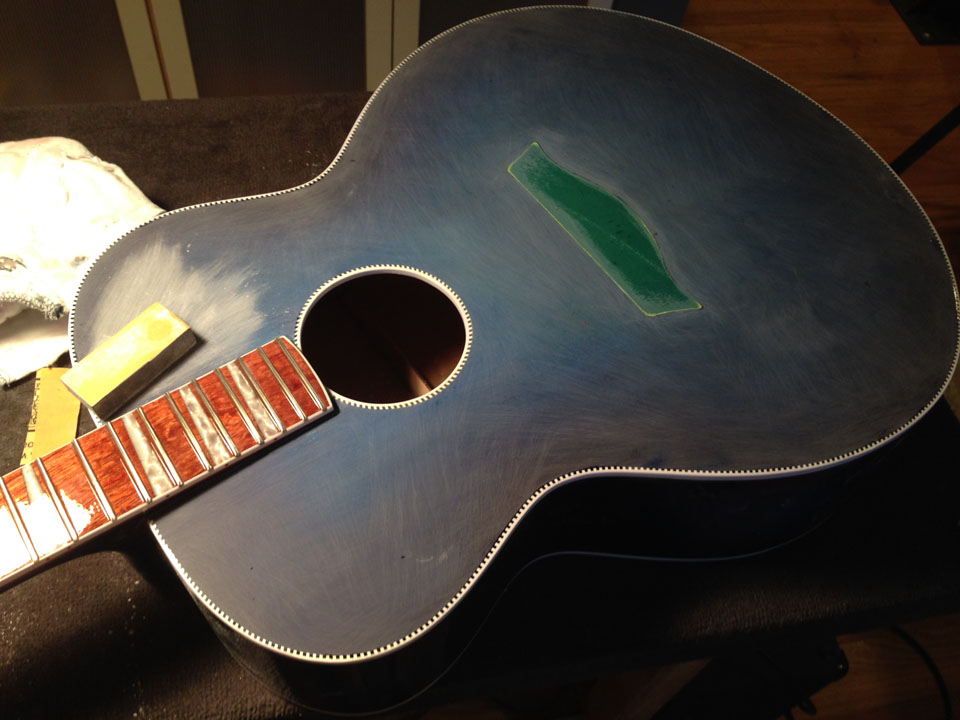

THE FINISHING PROCESS IS COMPLEX AND TIME-CONSUMING. ROUGHLY HALF THE BUILD TIME IS SPENT IN FINISHING. THIS IS THE BODY AFTER THE FIRST SEALER COAT IS APPLIED.

THE "BLUEBURST" COLOR COATS ARE SPRAYED. BINDING IS TAPED AND ALSO SCRAPED. THIS STEP LOOKS DULL; CLEAR COATING BRINGS OUT BOTH COLOR AND DEPTH OF GRAIN.

FIRST CLEAR COAT IS FLATTENED POST-CURE. WE CURE OUR FINISHES WITH AN INFRA-RED BAKING PROCESS.

SECOND CLEAR COAT SEES SPECIAL SANDING ATTENTION PAID TO SMALL FLAWS AND EDGES OF BINDING.

BACK OF HEADSTOCK IS NOW DEAD FLAT; FINGER POINTS OUT TINY FLAW THAT WILL BE CORRECTED BEFORE NEXT CLEAR COAT.

BODY AND NECK HEEL ARE ABSOLUTELY FLATTENED AND READY FOR FINAL CLEAR COAT. IN ALL, ENTIRE SURFACE OF GUITAR IS SANDED NO LESS THAN FOUR TIMES.

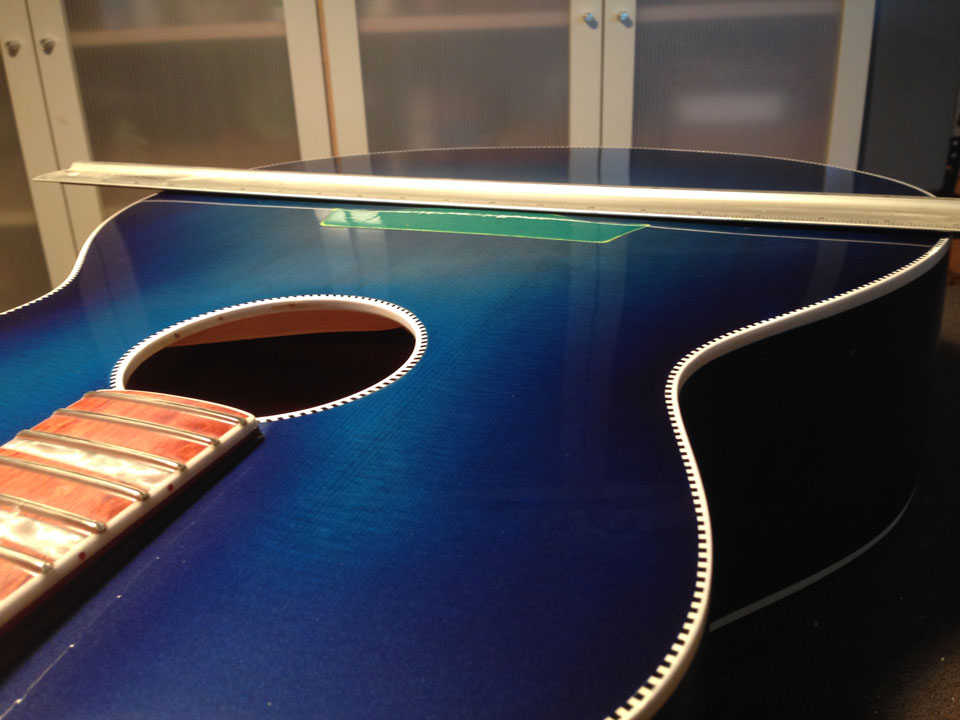

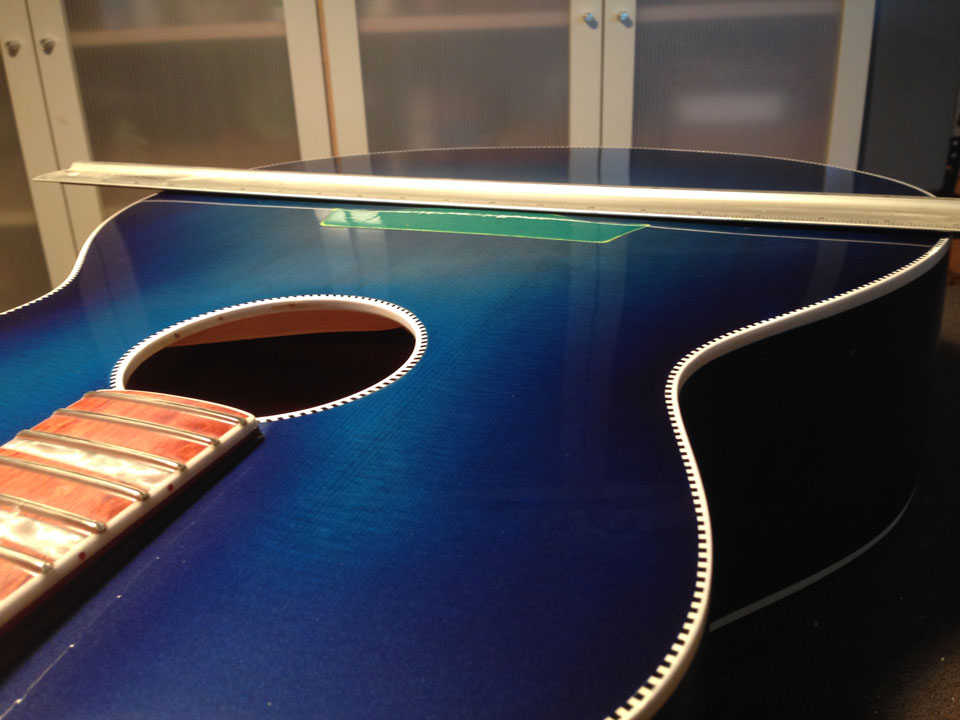

STRAIGHT EDGE ON NEWLY-BUFFED 700C SHOWS SPHERICAL RADIUS OF TOP. BACK IS SAME; AIDS BOTH STRENGTH AND SONIC PROJECTION.

TAPE MASK FOR BRIDGE IS CUT AND PEELED AWAY TO REVEAL RAW TOP WOOD. BRIDGE IS GLUED TO RAW WOOD AND CLAMPED UNTIL CURED.

VERY REFLECTIVE FINALLY-BUFFED SURFACE OF 700C IN "BLUEBURST" FINISH.

HEADSTOCK TAKING SHAPE WITH 12 GOLD TUNING MACHINES. "HALO" SCRATCHES IN CLEAR COAT FILL WITH WAX IN FINAL STEP.

BACK OF HEADSTOCK SHOWS PRECISE LOCATION OF 12-STRING TUNERS SO ADJACENT KEYS DON'T INTERFERE WITH EACH OTHER WHEN TURNED.

EACH ACOUSTIC BUILD SPENDS A MINIMUM OF 96 HOURS WITH A TONE-RITE DEVICE FITTED TO THE STRINGS. THIS "OPENS" THE WOOD SONICALLY, SIMILAR TO MONTHS OF "PLAYING" IN.