RICKENBACKER AND MADELEINE STRINGS ACOUSTIC GUITARS

THE BUILD PROCESS

BODY MOLD, LINING, AND BRACING

This slide show follows roughly a step-by-step progression.

Slides advance every 10 seconds, but you can also go forward or backward using the arrows on each slide.

OUR WORKSHOP AS WE BEGIN AN ACOUSTIC BUILD. A BODY MOLD IS IN THE FLOOR VISE AND BRACING PATTERNS ARE ON THE WALL.

THIS IS THE BODY MOLD FOR A 700C JUMBO WITH THE BODY IN PLACE. IT'S JUST RECEIVED THE LINING STRIPS AND WILL BE SANDED TO LEVEL THE SIDES.

HERE, A CLASSICAL "HOOP", OR BODY SHELL, IS FITTED INTO ITS MOLD PRIOR TO GLUING IN THE LINING STRIPS. THE NECK HEEL AND TAIL BLOCKS HAVE BEEN GLUED AND ARE CLAMPED INTO PLACE UNTIL THE GLUE DRIES.

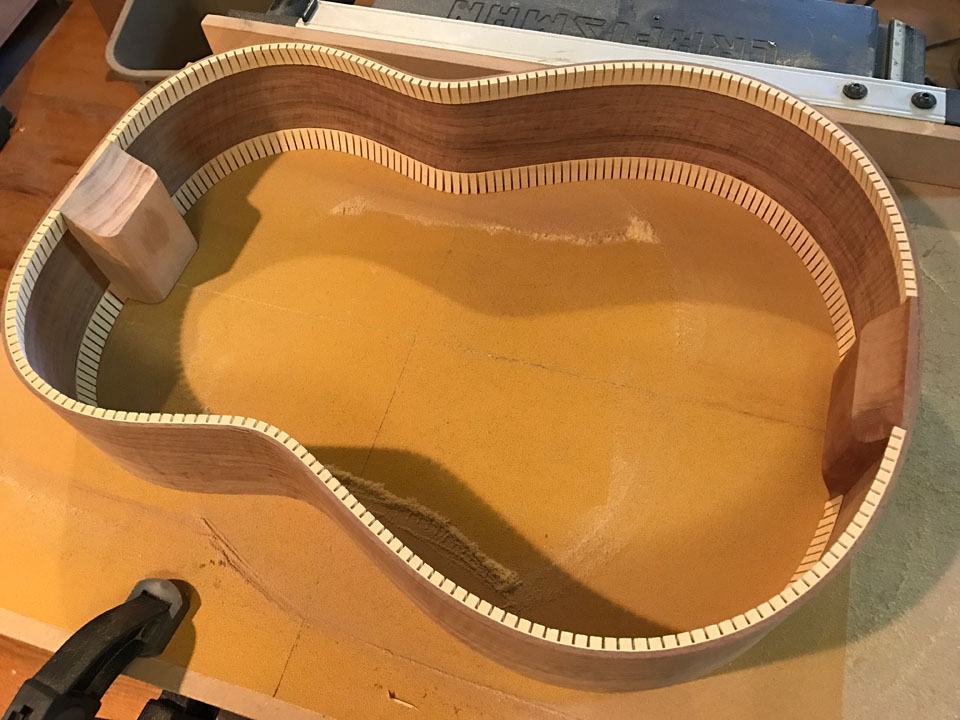

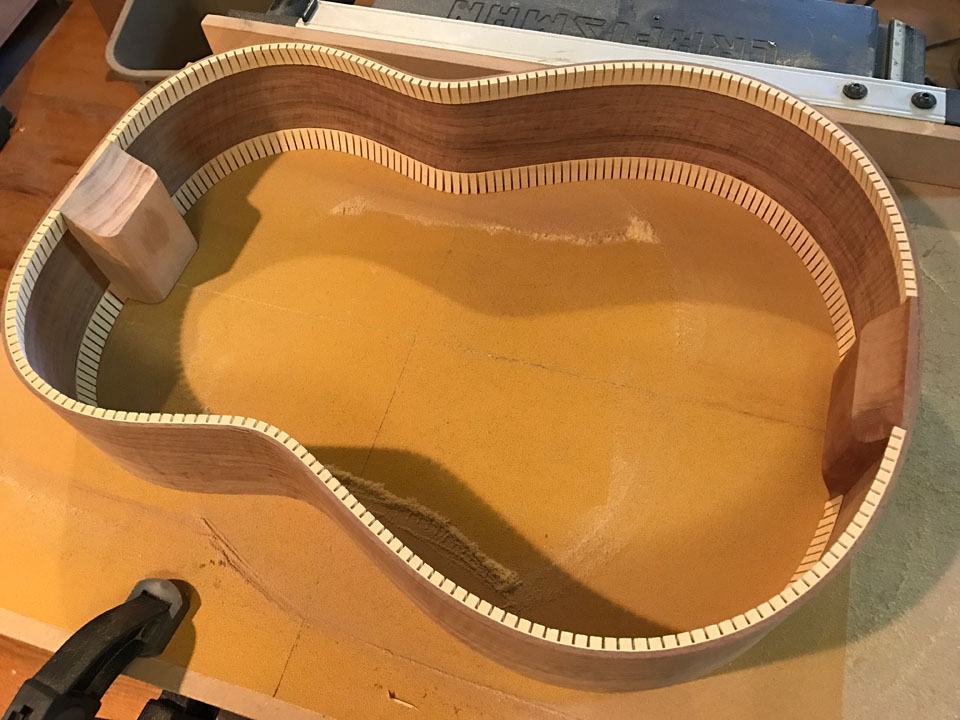

THE CLASSICAL "HOOP" IS HAVING ITS LINING STRIPS GLUED INTO PLACE. THESE PROVIDE A SURFACE ONTO WHICH THE TOP AND BACK ARE GLUED.

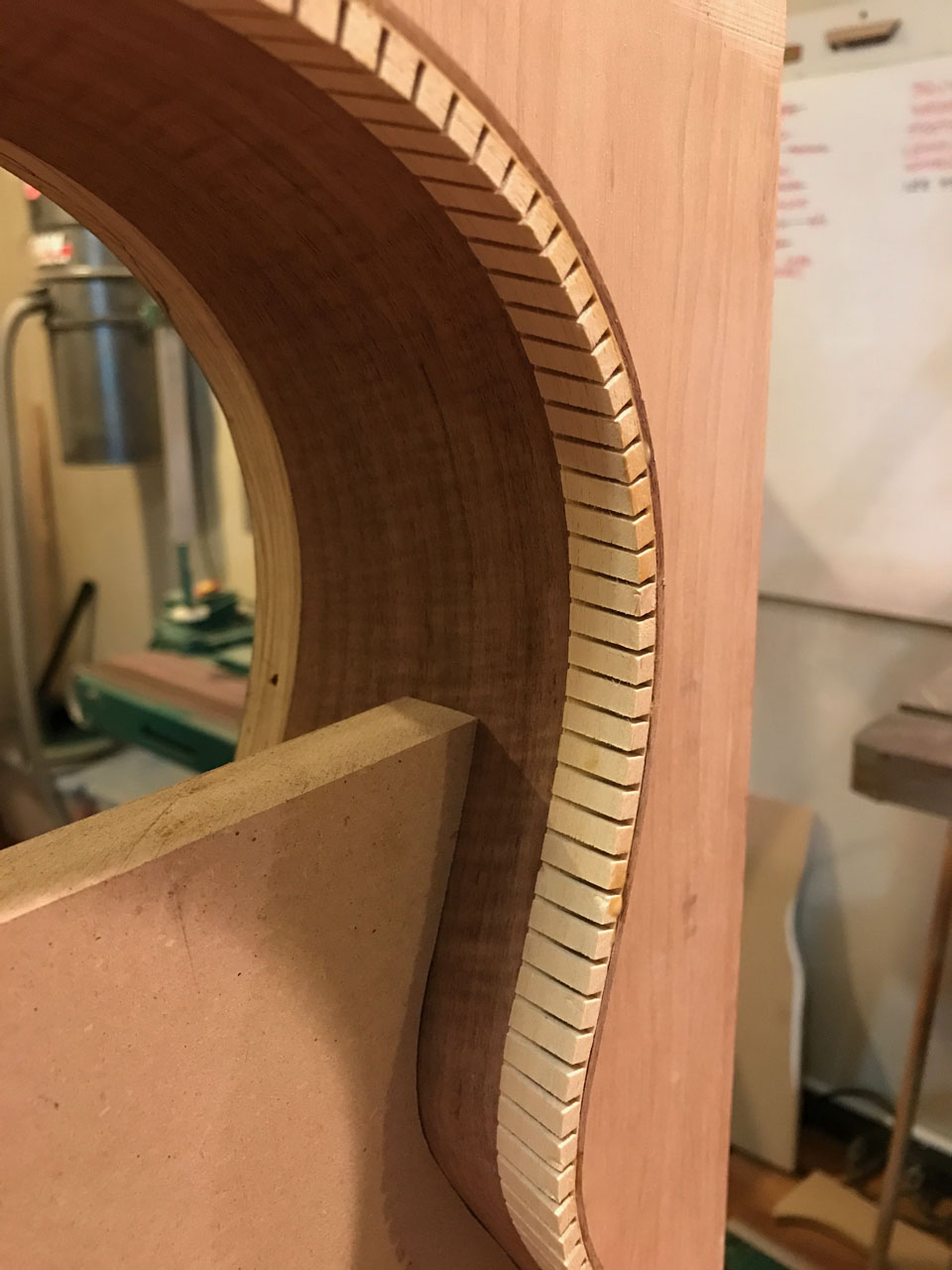

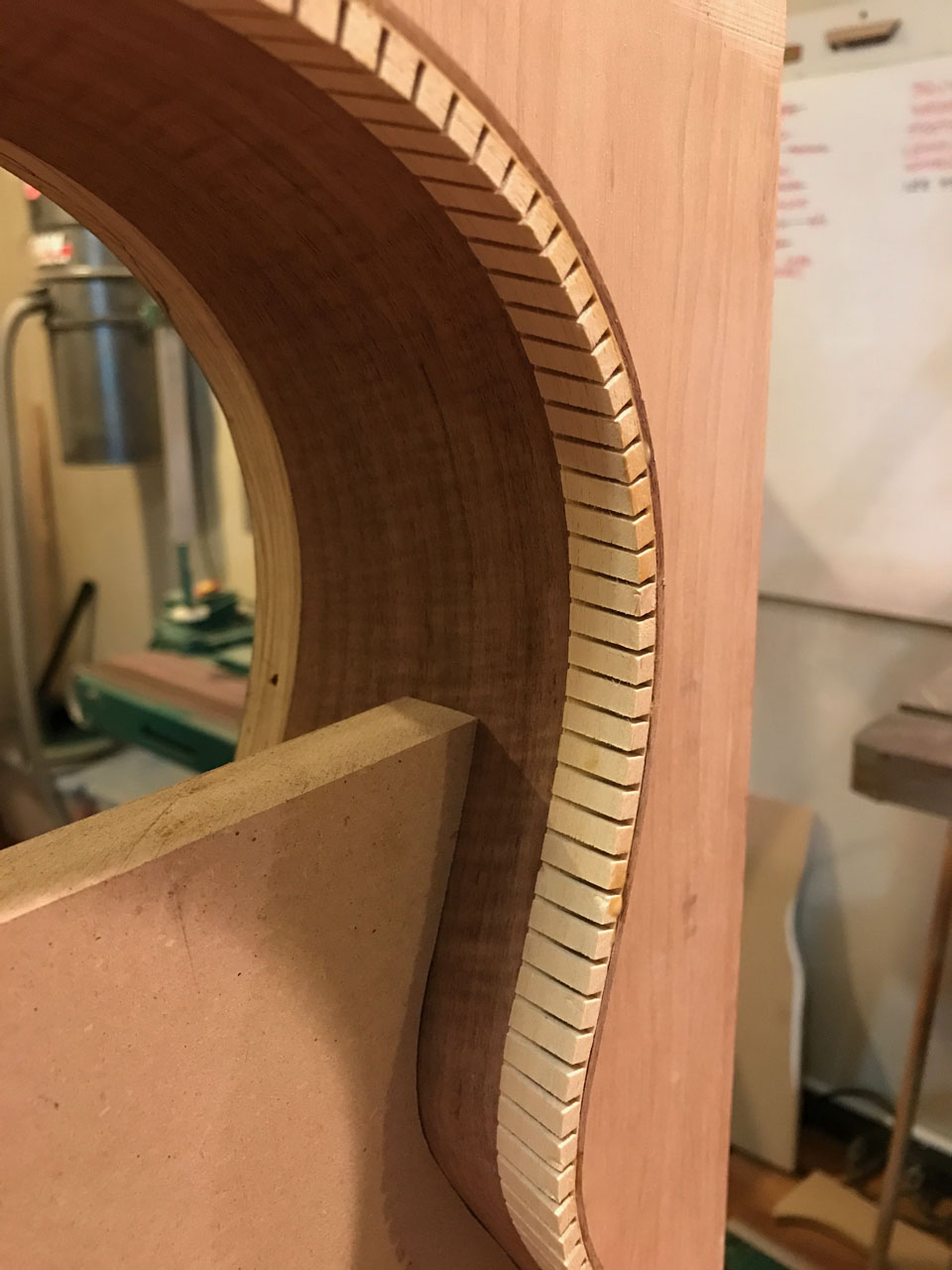

THE CLASSICAL BODY IN CLOSEUP. THE LININGS HAVE BEEN GLUED INTO PLACE, AND NOW THE SIDES ARE SANDED LEVEL WITH THE LININGS.

IN THE CLASSICAL GUITAR, THE HEEL BLOCK IS CUT BACK FROM TOP AND BACK TO ALLOW THE ENTIRE SURFACE TO VIBRATE AS ONE PIECE.

THE CLASSICAL BODY "HOOP" REMOVED FROM THE MOLD. NOTE THAT THE NECK HEEL BLOCK IS ALSO CUT BACK, BUT ON THE BACK SIDE ONLY. THE TOP IS GLUED TO THE HEEL BLOCK IN THIS AREA.

BY CONTRAST, THIS IS THE NECK HEEL BLOCK FOR A STEEL-STRINGED 730S. IT IS NOT CUT BACK, FOR EXTRA STRENGTH AGAINST STRING TENSION.

700C JUMBO BODY "HOOPS" REMOVED FROM THE MOLD, WITH LINING STRIPS AND BLOCKS IN PLACE.

THE TAIL BLOCK FOR A 700C JUMBO IS SHOWN.

A 700C JUMBO BODY "HOOP", SEEN FROM THE BACK SIDE. THE "L" SHAPED NECK HEEL BLOCK AND TAIL BLOCK ARE BOTH SHOWN.