RICKENBACKER AND MADELEINE STRINGS ACOUSTIC GUITARS

THE BUILD PROCESS

INSTALLING THE BINDING

This slide show follows roughly a step-by-step progression.

Slides advance every 10 seconds, but you can also go forward or backward using the arrows on each slide.

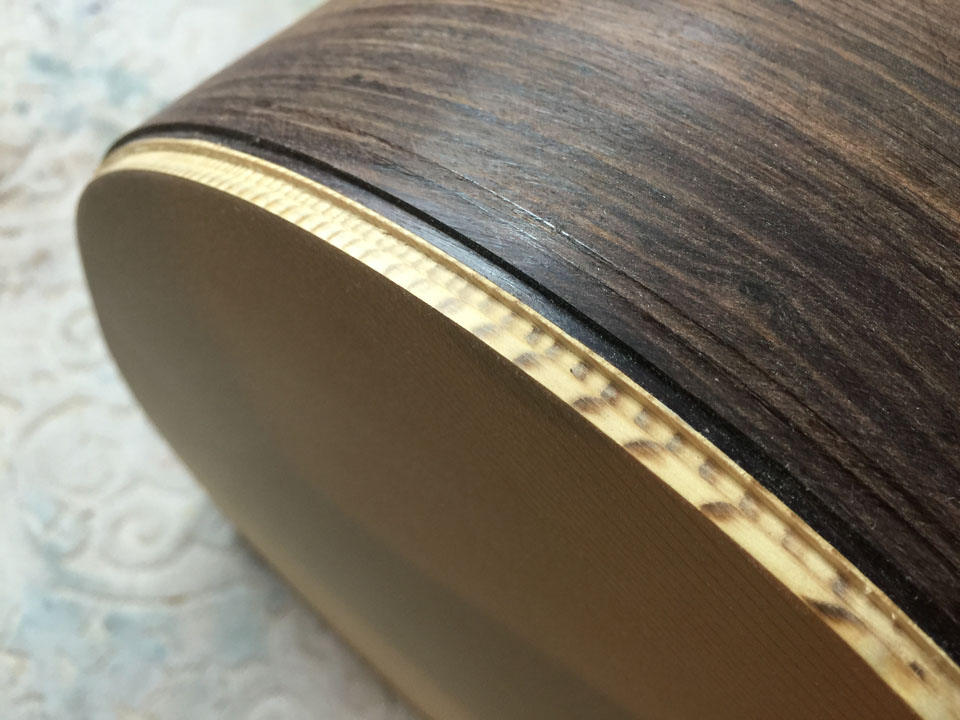

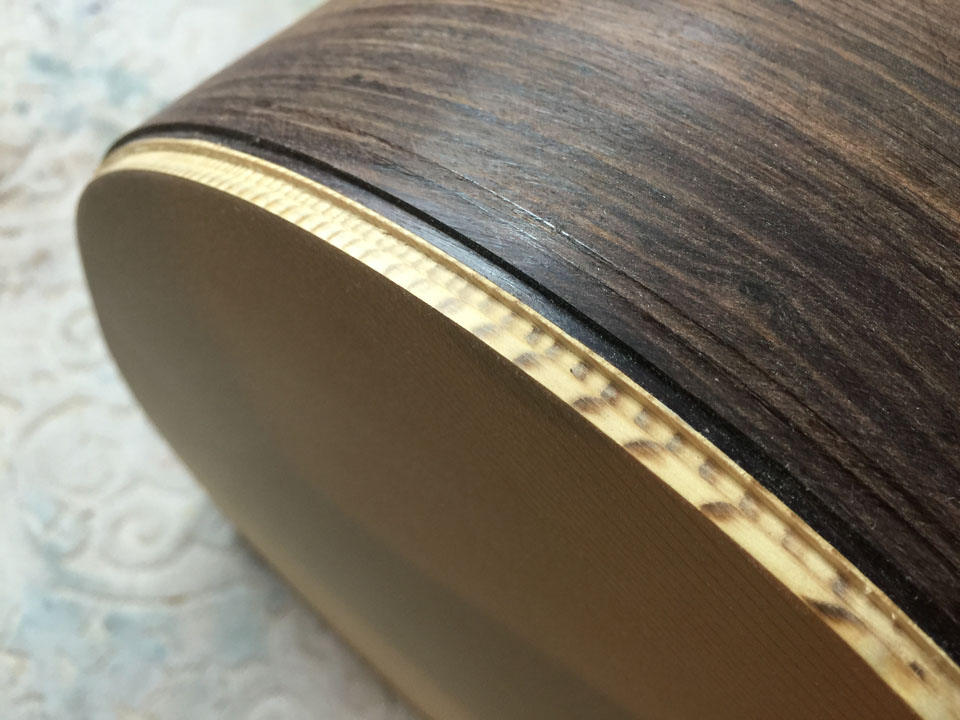

THE CHANNEL THAT IS CUT FOR THE PURFLING AND BINDING IS A DOUBLE-STEP CONFIGURATION. THE INNER STEP IS TO NEST THE "CHECKERBOARD" PURFLING, OUTER STEP IS FOR THE WHITE OR TORTOISE OUTER BINDING.

TOP AND SIDE OF A SPRUCE/ROSEWOOD 730S DREADNOUGHT, SHOWING THE DOUBLE-STEP ROUTING PROCESS.

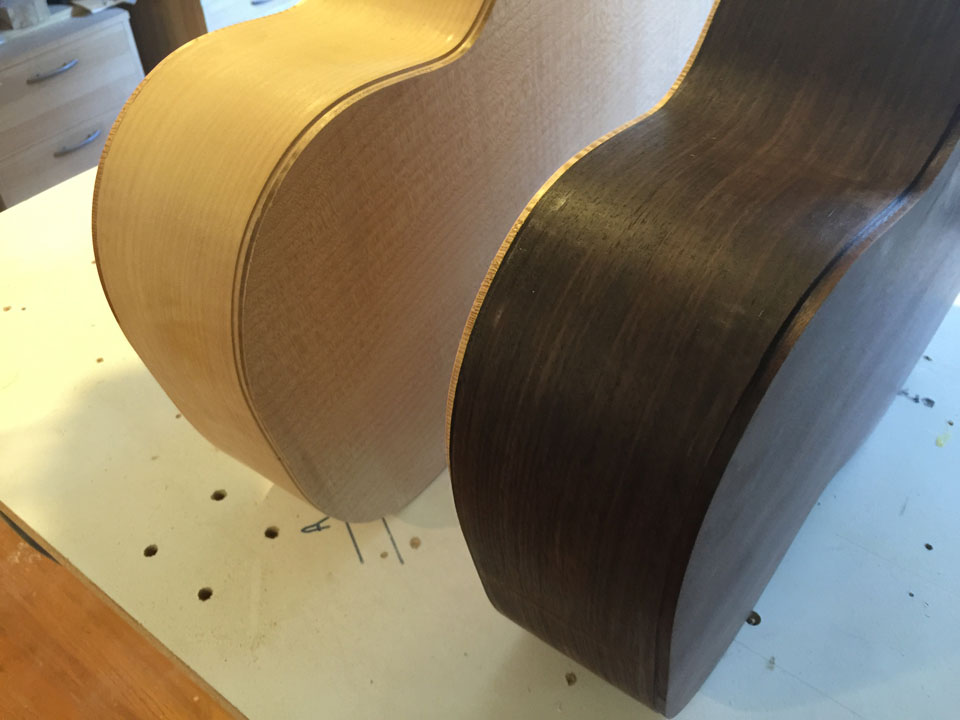

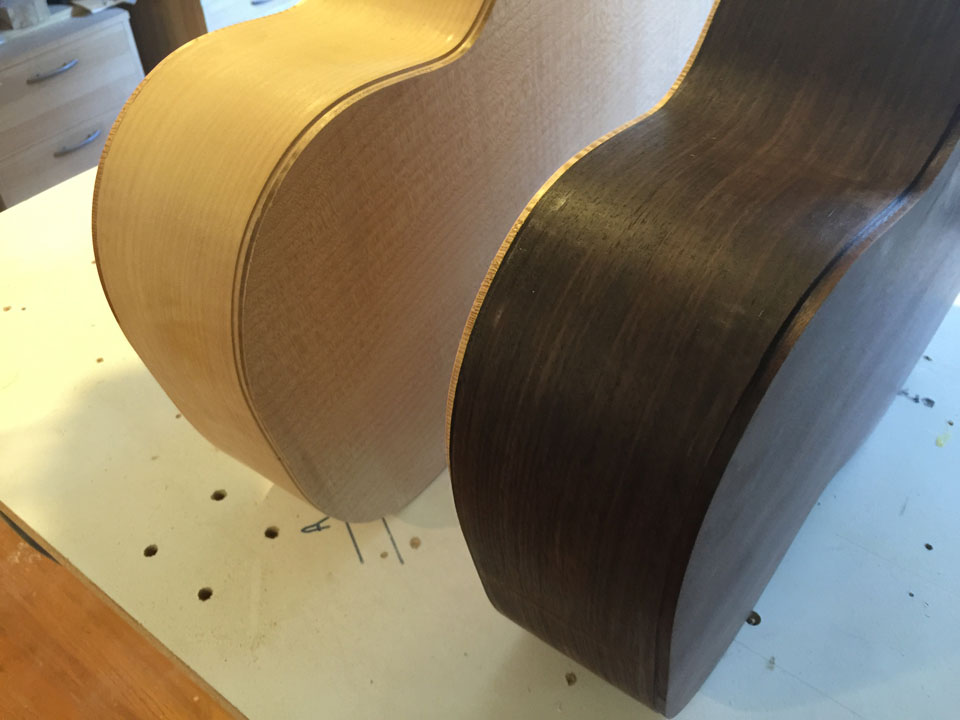

TWO 700 BODIES, A "C" AND AN "S", WITH THEIR BINDING ROUTS HAVING BEEN CUT.

ANOTHER VIEW OF THE SAME 700 BODIES.

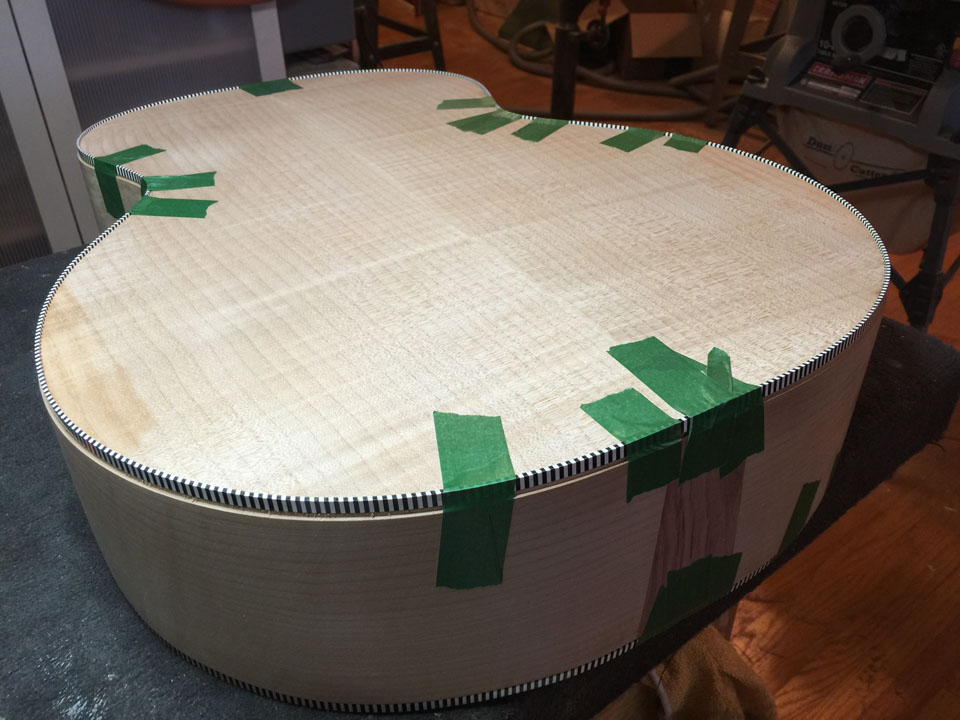

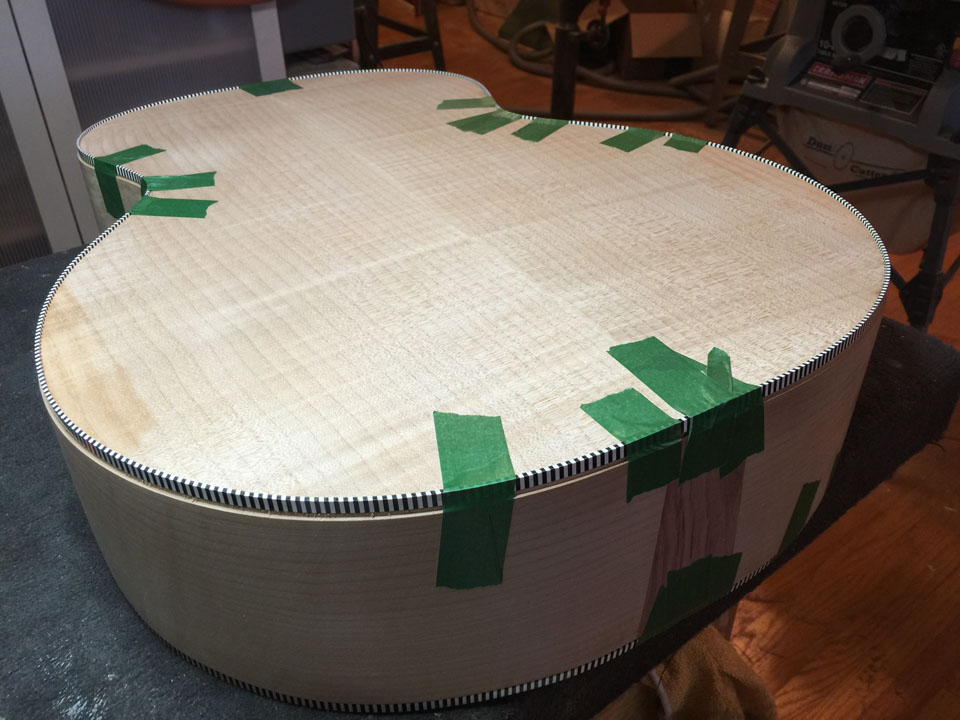

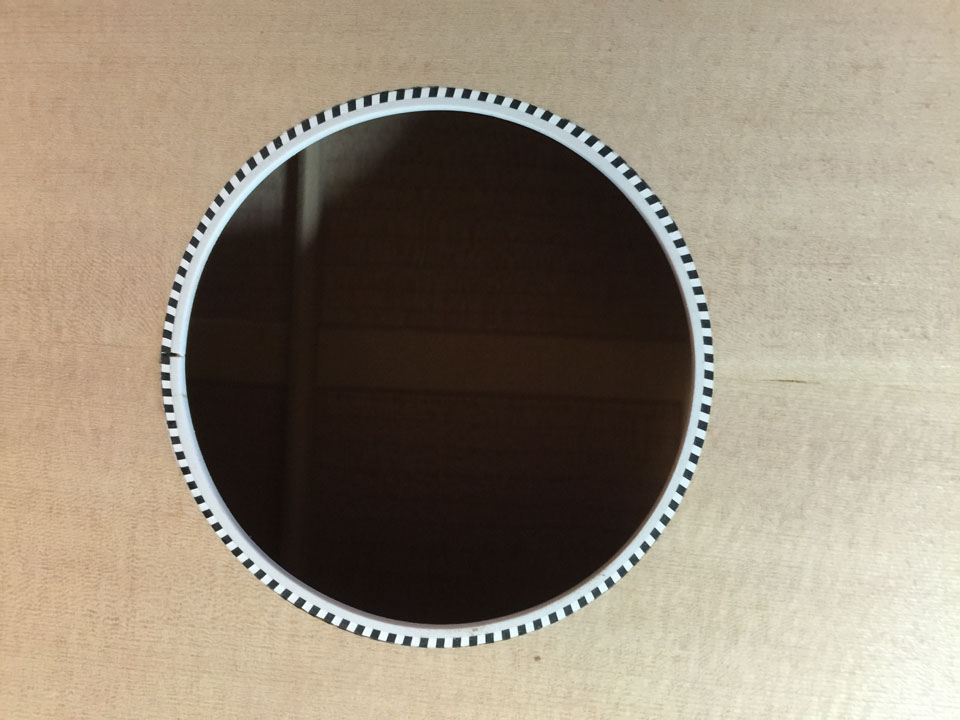

"CHECKERBOARD" PURFLING IS GENUINE CELLULOID, COMES IN STRIPS, IS GLUED INTO PLACE WITH SPECIAL GLUE CONCOCTION.

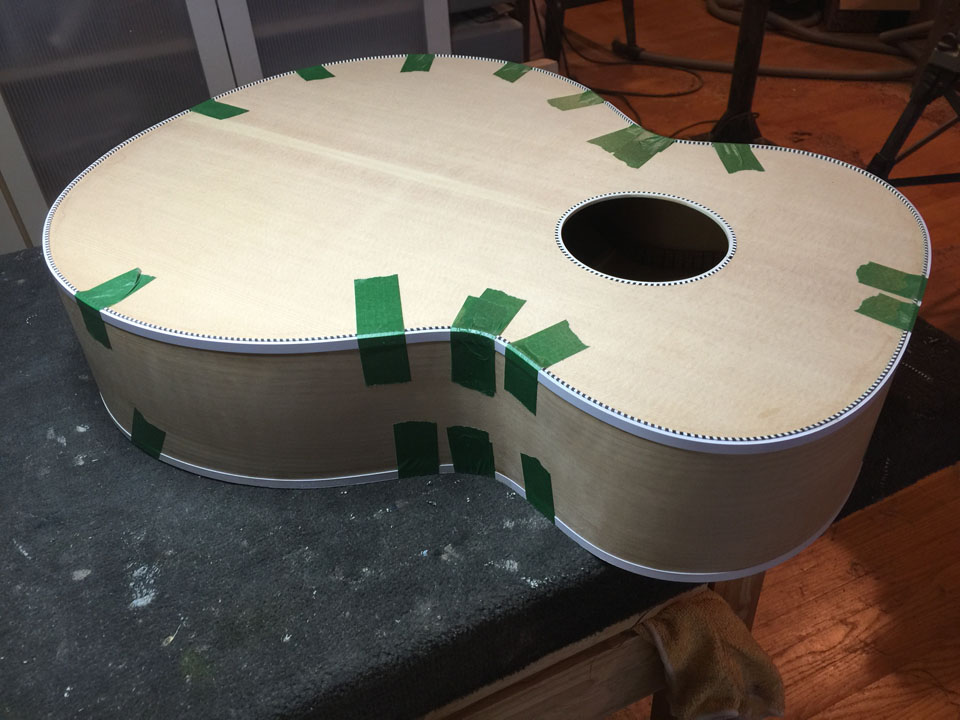

BINDING IS TAPED WHILE GLUING TO HOLD THE CURVE OF THE BODY. THE FITMENT MUST BE VERY TIGHT AND PRECISE; NO GAPS ARE PERMITTED.

DETAIL OF "CHECKERBOARD" PURFLING AFTER IT HAS BEEN GLUED ONTO A 700S BODY, AND THE TAPE REMOVED. NOTE THAT IT STANDS A LITTLE "PROUD" OF THE TOP SURFACE; THIS AND BINDING ARE LATER SCRAPED FLUSH.

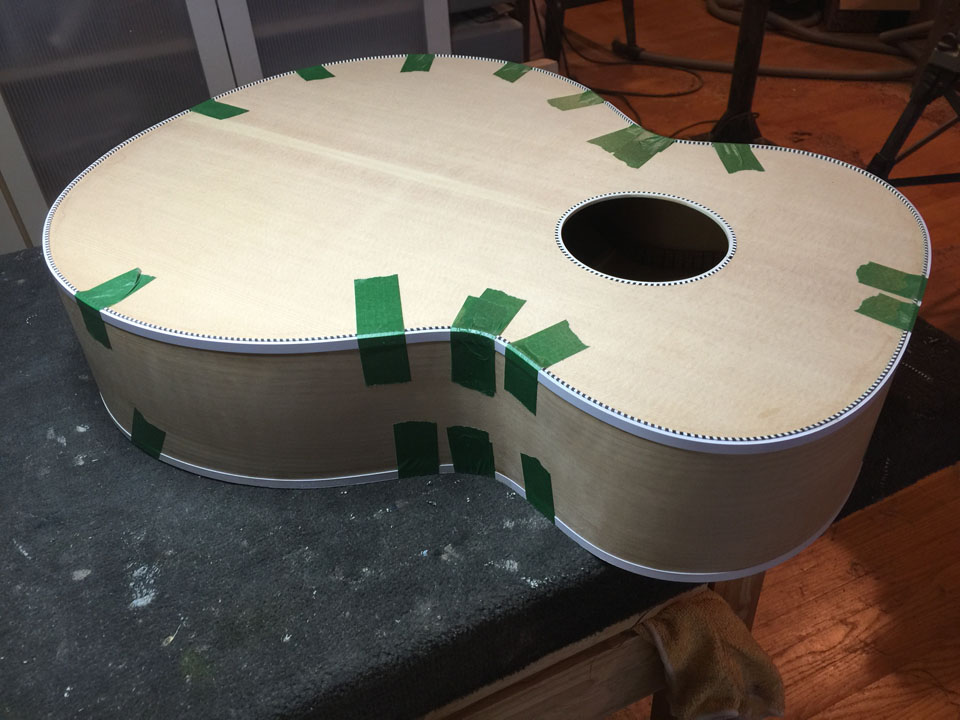

WHITE BINDING BEING GLUED TO THE "BLUEBURST" SOUND SAMPLE 700C JUMBO BODY.

THE TWO BOUND 700 BODIES WITH THEIR WHITE BINDING TAPED AND DRYING. TOP AND SIDES OF BINDING WILL BE HAND-SCRAPED FLUSH.

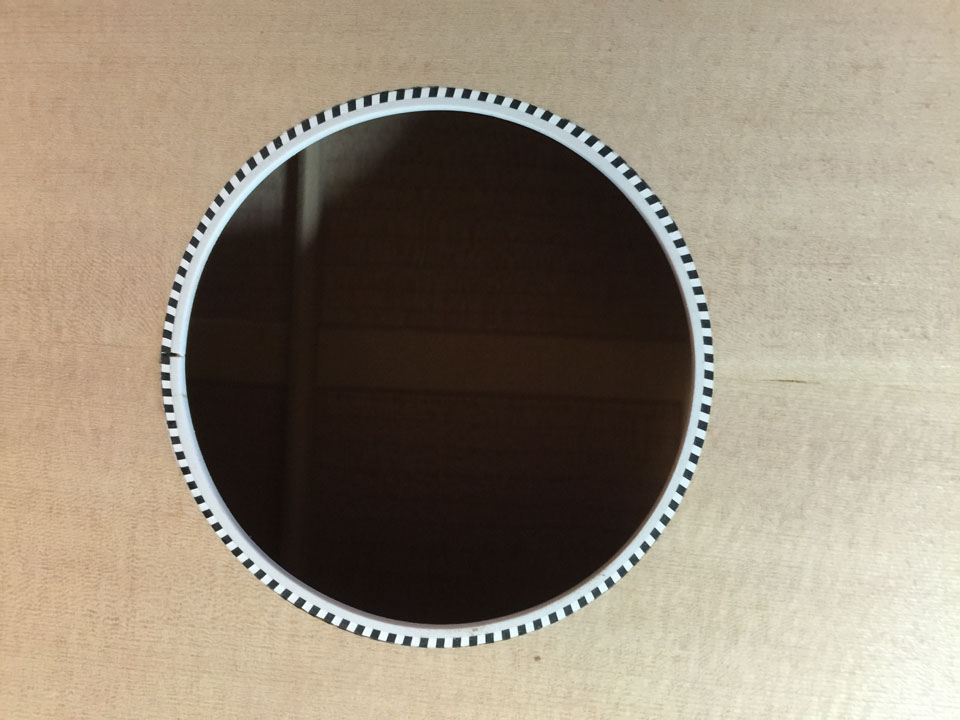

SOUND HOLE MAY BE CUT AND BOUND AT ANY STAGE OF CONSTRUCTION. THIS ONE HAS JUST BEEN SCRAPED FLUSH WITH THE TOP.