1967 JETGLO 360 "F" RESTORATION

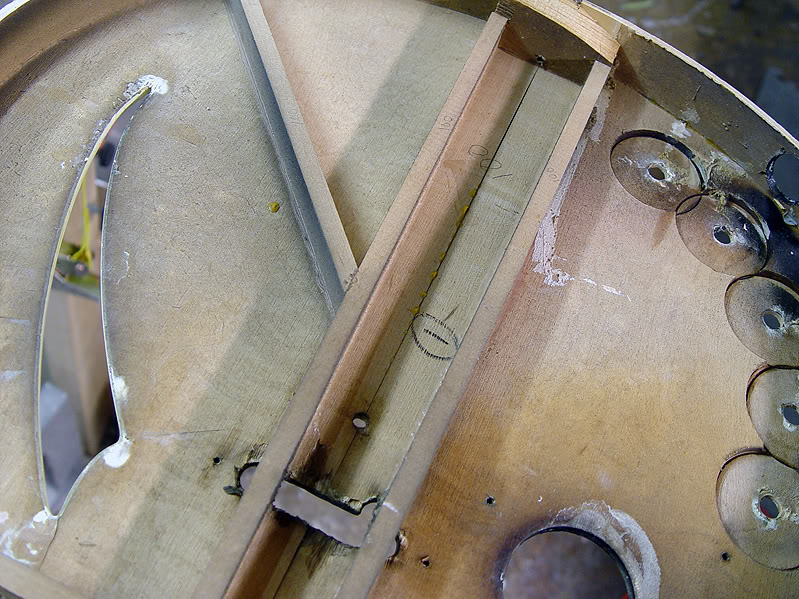

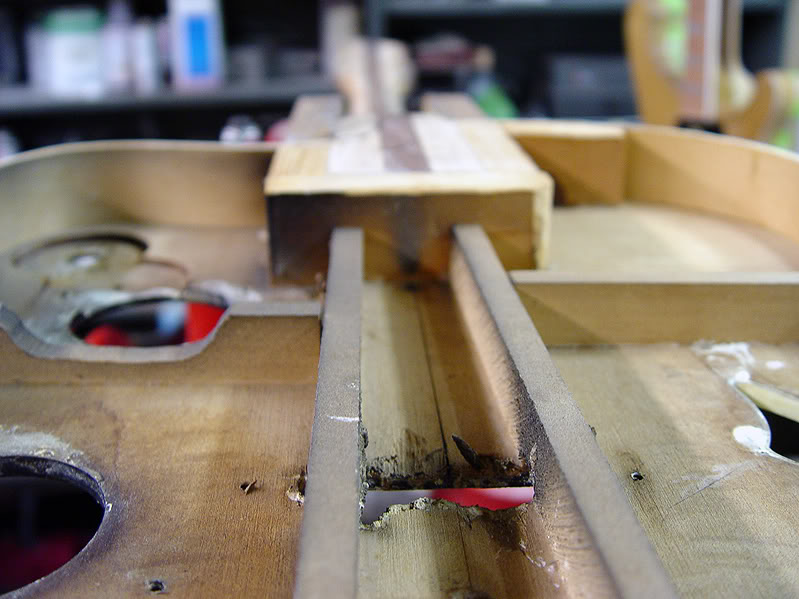

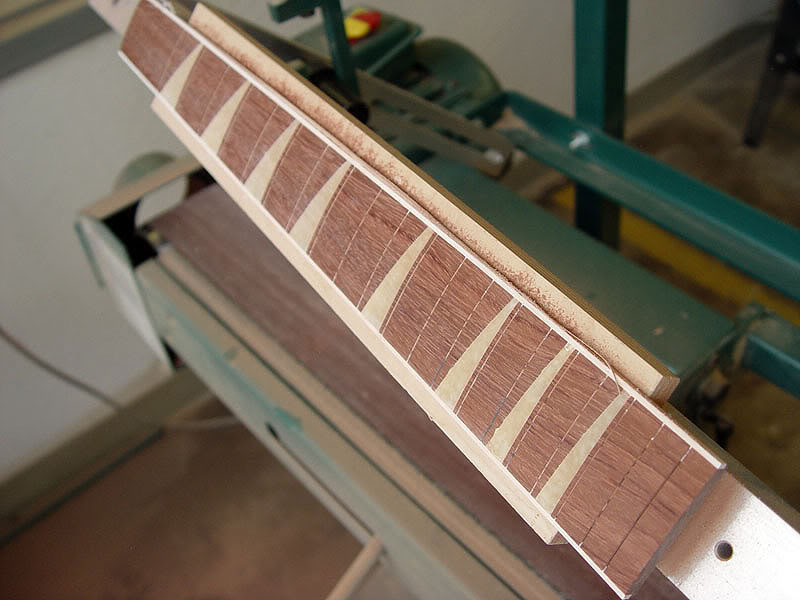

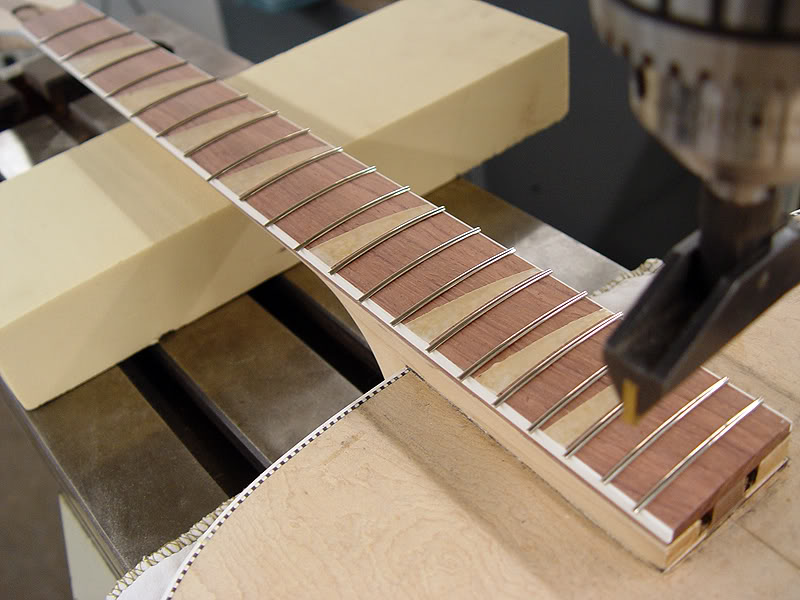

A rare peek--in slide show format--into the innards and restoration process of a rare second-series "F"-bodied Rickenbacker from 1967. Construction of these "F" bodies used bent sides with flat panels glued to the sides for both top and back. The tops were 9/32" thick and the backs 1/4". You can see the 2" Forstner bit counterbores used to thin the top in the areas of the switch and pots, so that standard-length pots and in-stock Switchcraft leaf-type switches could be used. There were two longitudinal braces and two staggered braces at the waist to strengthen the top and back. One waist brace is heavily cut away for wiring to run through. Two 2" through holes (hidden by the pick guard) allowed wiring access. The wiring harness was brought through these 2" holes, and fish tapes were used to pull the pots through their mounting holes from the back. A slot connects the two 7/8" output jack holes, because the jacks had to be installed from the outside, unlike every other semi-hollow Rickenbacker model, which had the jacks brought through the body side from the inside. These construction details are unique to the "F" models.

This particular example was purchased by the owner from photos, and when it arrived it was discovered that the back had been split, and was repaired inexpertly with Bondo and touched up with rattle-can enamel.

The back was removed first, giving access to the inside of the guitar, and restoration began by replacing this panel. Because Jetglo was to be the finish color, both top and back needed to be made absolutely flat. The photos of the finished guitar bear out the success of this tedious surfacing. INTERESTING BIT OF TRIVIA: A special long version of the classic die-cast "R" tailpiece was used on the "F" models, and since the "F" model of the second series also was available as a 12-string, all the tailpieces were molded with 12 string slots, and only 6 of the slots were used for 6-string versions.